Special Mid-Month Issue November 15, 2011 Read this issue on the Pure Water Occasional's Website |

|---|

The Amazing Permeate Pump

by Gene Franks

For many years attempts have been made to replace the conventional bladder-tank storage system that is used on almost all undersink reverse osmosis units. Although the bladder tank works well, it has a serious flaw. As the tank fills and pressure builds, the reverse osmosis unit must push against this increasing pressure. The back pressure from the tank makes the RO unit very inefficient. In fact, when the pressure tank is almost full and is, therefore, exerting maximum back pressure, the RO unit is so inefficient that it may be sending more than 90% of the water it processes to drain.

There have been many efforts to replace the bladder tank system.

For example, a few years ago a non-pressurized tank was introduced that contained a small electric pump that turned on and delivered water to the faucet upon demand. The "atmospheric" tank eliminated back pressure but introduced a whole new set of problems. The product soon went away.

Many versions of a "water on water" undersink RO have come and gone over the last two decades. In this system, the RO unit produces into a flexible bladder inside an unpressurized tank. When the user opens the faucet, untreated tap water rushes into the tank to squeeze the bladder and force treated water out through the faucet. The early models of the water-on-water units had numerous problems and soon went away. The water on water style, even if it works perfectly, consumes an amount of water equal to the permeate to push the permeate out of the tank. New water on water systems keep appearing from time to time. We'll see.

A current new "water saving" design called "zero waste" uses a conventional bladder tank but employs an electric pump to pressure the RO unit's reject water back into the home's water supply. In my opinion, "zero waste" ranks high on the list of the world's worst ideas ever.

The much-cursed, inefficient, but very reliable bladder tank still dominates the market. It is still on top because it is simple, essentially problem free, and relatively inexpensive.

The Permeate Pump: An Effort to Enhance, Not Replace, the Bladder Tank System

The permeate pump was created to overcome the inefficiency of the bladder tank RO system. Unlike electric "booster" pumps, which increase the water pressure going into the RO unit, the permeate pump takes energy from the RO unit's drain water stream and uses it to overcome the back pressure from the storage tank. It allows the RO unit to produce its "permeate" (product water) into a pressure-free chamber of the pump rather than directly into the pressurized tank itself. The unit's reject water, or "brine," is used to provide energy which is stored and used to push the permeate into the storage tank.

|

|---|

This nifty graphic supplied by permeate pump manufacturer Aquatec shows how the pump works. The permeate pump relies on a simple design. The pump runs without electricity and is completely automatic. It can be installed with a hydraulic shutoff (as in the graphic) or without one. Without the shutoff valve, the pump itself shuts off the RO unit's production when the storage tank is full. Larger image. |

How Permeate Pumps Work

Reverse osmosis is a pressure-driven process. In simplified terms, if an undersink RO unit is fed with 60 psi inlet pressure, it runs wonderfully when its faucet is open and it isn't putting water into the pressurized storage tank. However, when the faucet is closed and the RO unit is filling the storage tank, it does not enjoy the advantage of the full 60 psi. When the tank is partially full, for example, and has 30 psi pressure, the RO unit must use 30 of its 60 psi just to overcome the back pressure from the tank and it is running very inefficiently.

Unlike electric pumps that boost inlet pressure to reverse osmosis units, the unique "permeate pump" enhances performance without actually providing additional pressure for the inlet side of the unit. The permeate pump, instead, greatly reduces the back pressure from the RO unit's storage tank. This allows the RO membrane to take full advantage of the pressure that it has.

Permeate is water treatment jargon for the product water of the reverse osmosis unit--water that has been treated by the membrane, the water you're going to drink. Brine is the rinse water, the water that is carrying away the impurities rejected by the membrane, the water that will ultimately go down the drain.

The pump works by storing the hydro power of the brine, the reject water, and using that energy to power the permeate under pressure into the unit's storage tank.

The result is a quite remarkable increase in unit efficiency. Since the RO unit can fill the tank much faster without the hindrance of back pressure, far less reject water is used, and the permeate, or product water, is purer.

|

|---|

The compact, grapefruit-sized pump mounts to the undersink wall with a clip that's provided. It must be installed with the indicator arrow pointing up, as shown in the picture. On our permeate pump units, we color code the tubing for easy installation. |

Here's how the flow through the pump works, with reference to the picture above:

Brine In. Black Tube. Water leaves the membrane housing's brine port and goes to the pump, under pressure.Its flow is limited by the RO unit's brine line flow restrictor.

Brine Out. Yellow Tube. After providing power that is stored in the left side of the pump (think of it as winding a clock spring to store energy for later use), the brine exits and goes to the undersink drain pipe via the yellow tube.

Permeate In. White Tube. The permeate comes direct from the membrane housing and enters the right chamber of the pump. There is almost no back pressure. It collects in this pressure-free chamber until the brine side of the pump releases energy and powers it out of the chamber.

Permeate Out. Orange Tube. Powered by the stored energy from the brine, the water is forced into the unit's pressurized storage tank via the orange tube.

Performance Enhancement is Spectacular

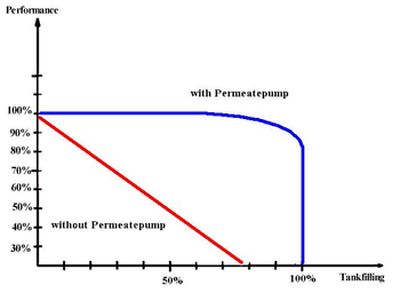

Here's a chart from the manufacturer's website showing typical pump performance.

|

|---|

The blue line illustrates the performance of the RO unit operated with a permeate pump (installed without a shutoff valve). The red line is performance of a conventional RO unit. The permeate unit operates at full efficiency almost to the point where the storage tank is full. (Standard units normally shut off at about 60% of tank capacity to avoid the extra low performance that would occur after that point. As the graph shows, at the 60% shutoff point the RO unit is about 40% efficient.) Larger Image |

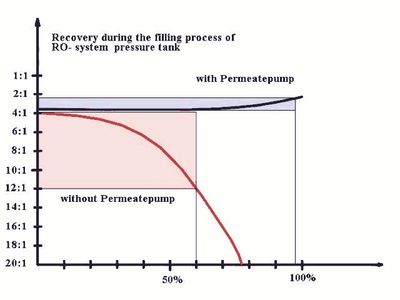

Here's another of the manufacturer's performance graphs.

|

|---|

The black line is production with the permeate pump and the red line represents the production pattern of a standard RO unit without a permeate pump. The ratio figures on the left of the graph represent typical RO performance. The unit starts with a ratio of four parts to drain for each part that reaches the storage tank. By 60% tank capacity (the point where auto shutoff valve cuts off production in the non-pump unit), the permeate pump unit is still producing at the original 4 to 1, but the standard unit is now sending 12 parts to drain for each part that reaches the storage tank. (I have no explanation for the upward movement of the permeate line as it approaches the full-tank line.) Larger Image. |

Our Informal Tests

We have tested water usage by RO units with and without the permeate pump on many occasions. The pump's performance is always impressive. We've tested with various types of shutoffs, with and without shutoffs, with small tanks and large tanks, with full tank fillings and "top off." I decided to do a single, easy test for this article, using my home RO unit.

The RO unit is an older Black and White unit equipped with a standard Payne shutoff system. It has a fairly old 18-gallon-per day Osmonic membrane. The tank is the smallest we sell, a one-gallon metal. The unit hasn't been serviced for more than a year and the tank needs air. The unit has a several-years-old ERP1000 permeate pump.

I started with a full tank, then drew off a quart of water and captured the brine as the unit refilled the tank. I then removed the permeate pump and set the unit up as a standard unit with the same Payne shutoff system. Again, I drew off a quart of water and captured the reject water.

The results:

Total brine produced while refilling one quart of water with the permeate pump--1 gallon plus about 1/4 cup. Essentially, the "theoretical" 4 to 1 setup of the unit. (The unit has the standard 180 ml/m flow restrictor used with 18 gpd membranes.)

Total brine produced while refilling one quart of water without the permeate pump-- 7 quarts.

In other words, the permeate to brine ratio with the pump was 4:1, without the pump, 7:1. This is essentially the ratio we've seen consistently with more extensive permeate pump trials we've done in the past. With the permeate pump, the RO unit uses slightly over half as much water as the standard unit.

Applications

Almost any existing RO unit can be retrofitted to run with a permeate pump. The exception is the "manifold" style unit in which the tubing between the shutoff system and the membrane are not accessible. Hydrotech units, for example, are built in a manifold and cannot be upgraded to operate with a permeate pump.

We believe any RO unit will perform better with a permeate pump. Situations where the pump helps most are installations with low inlet pressure. High pressure applications where a standard unit runs well, however, will also benefit considerably from the addition of a permeate pump.

With or Without ASO

A decision that you must make if you plan to add a permeate pump to an existing RO unit (or if you have a choice in the matter when you purchase a new RO unit with permeate pump) is whether to install it with a conventional shutoff system (ASO) or to leave off the shutoff and allow the pump itself to shut down water production when the storage tank is full.

There are pros and cons to each.

A standard shutoff system stops water production when pressure in the storage tank reaches about 2/3 (60%) of the pressure of the unit's feed water. In other words, if your city tap water pressure is 60 psi, your conventional RO unit will stop producing water when pressure in the storage tank reaches about 40 psi. With this situation, if you add a permeate pump to the system without removing the shutoff system, the full tank pressure will still be 40 psi, although the tank will fill much faster and the unit will run much less water to drain while filling the tank. However, if you install a permeate pump and remove the shutoff system, the RO unit will now put almost the full 60 psi of available pressure into the tank.

TDS Creep

Without getting too technical, there's a disadvantage to without-shutoff installation known as "TDS creep." This describes a problem that occurs with permeate pump units when only small amounts of water are taken from them and they frequently turn on and run briefly to refill the storage tank. (This, obviously, is standard operation condition for most home units.) Under these circumstances the Total Dissolved Solids (TDS) of the unit will read a bit higher than normal. This does not occur with units installed with the conventional shutoff system in place.

The choice, then, is between getting a bit more water, and consequently more pressure, in the storage tank at the expense of a slight diminution of RO performance. (The difference isn't enough that you will taste it, but your TDS meter may run a couple of parts per million higher.)

Here's a chart that compares the with and without shutoff installations.

| Inlet Pressure | "Full tank" with shutoff | "Full tank" without shutoff | Comment |

|---|---|---|---|

30 PSI |

18 Psi |

30 Psi |

With only 30 PSI inlet pressure, you would do better to boost the inlet pressure with an electric booster pump. Even with a permeate pump, you won't like the performance. |

40 PSI |

24 Psi |

40 Psi |

The without-shutoff option is definitely preferred. |

50 Psi |

30 Psi |

50 Psi |

Without shutoff is preferred, but either system will work well. |

60 Psi |

40 Psi |

60 Psi |

Either option will give excellent performance, but with the permeate pump, you'll run much less water to drain. |

Other Considerations

There are on the market 90% shutoff systems designed specifically for use with the permeate pump. We have found these to be unpredictable and prefer the standard 60% shutoff systems.

When the permeate pump came on the market, there was a single permeate pump, the ERP 1000, that was used for all RO units with membrane production up to 100 gallons per day. The manufacturer has recently added a second model, the ERP 500, which is a quieter version of the pump. It is used only with 50 gpd and less membranes. (The permeate pump makes a characteristic "thump" when it sends water to the storage tank. The ERP 500 is almost silent. The ERP 1000 is bothersome to some customers.)

The permeate pump is of no value with countertop RO units. Since these have no pressure tank, the pump is not needed. A countertop RO unit's performance is identical to an undersink unit's performance with a permeate pump.

Our Recommendation

If you have an undersink RO unit, you'll like it better with a permeate pump. The water savings and improvement in the general efficiency of the unit make adding a permeate pump worth considering. It usually costs less than $100 to add a permeate pump to your RO unit. (We have an "upgrade" kit that contains everything you need, plus instructions, for $77.)

The Pure Water Occasional is a project of Pure Water Products. Please visit our websites: Main Website: www.purewaterproducts.com. This site features our full range of products, plus instructions, technical articles, product manuals, and more. The Occasional's Website: www.purewateroccasional.net. In addition to archiving back issues of the email Occasional, this site houses a sizeable section about water contaminants, a "how things work," series, a new products section, a glossary of water treatment terms, and, "much, much more." Other Pure Water Products Sites: www.purauv.com

|

|---|