Special Mid-Month Issue September 15, 2011 Read This Issue from Our Website |

|---|

Sediment Filters

Water filters have many purposes. Some are designed to remove chemicals from water. Others remove metallic contaminants or "dissolved solids" or charged particles.

This article is about filters that remove suspended solids, variously referred to as turbidity, sediment or particulate.

In general terms, filters of this type are sieving devices. They are like nets that catch and hold particles that are too large to pass through the holes in their surface.

There are large backwashing filters that perform this function. They use beds of natural media like sand, garnet, and anthracite to filter out unwanted particles like dirt or iron rust. The newer versions usually rely on specifically designed and manufactured media with brand names like Filter Ag, ChemSorb, or Micro Z to catch particles. When particles are trapped in the bed, the filter "backwashes" by running water backward through the media bed to wash the unwanted particles down the drain.

|

|---|

| This "Spin Down" style sediment filter traps large particles and supports a high flow rate. It is manually purged by opening the valve (black handle) which blows out trapped particles and renews the filter. Spin Down filters use replaceable screens ( the core visible through the transparent housing) that are usually measured in mesh sizes rather than microns. With microns, the filter gets tighter as the numbers get smaller. With mesh, the filter gets tighter as the numbers get larger. |

This article, however, is about cartridge-style filters rather than backwashing filters. Cartridges are for the most part disposable items. Except in rare cases, they are not backwashed. They are used until they stop up, then they are discarded. Certain cartridges can be cleaned and reused. More of that later.

Rating Filters by Rejection Efficiency

Nominal, Absolute, and Beta Ratio.

These ratings are usually stated in micron size. The micron is a standard measure of size that is used by filter makers. The diameter of a human hair is about 90 microns. Sediment filters are used to catch particles 1/300 of that.

Most sediment filters are given ratings by their manufacturers that describe their effectiveness at removing particles down to a specified size. The most common of these are"nominal" and "absolute."

Nominal, according to the Water Quality Association (WQA), means that the filter will filter out at least 85% of the particles of the size it is rated for. In other words, a filter that is rated as a 1 micron nominal can be expected to pick out 85% of the particles that are 1 micron or larger from the water that passes through it.

Absolute, theoretically, means that the filter will reject virtually all of the particles of the given size. The usual expectation is a 3-log rejection--or 99.9%. Absolute ratings are usually used for the tightest filters and for purposes where efficiency really matters. For example, if a filter maker promises removal of E. coli, more or less 85% efficiency isn't good enough. If you're going to trust your life to the filter, you expect an absolute 3-log or 4-log rating at the very least.

The problem with the absolute vs. nominal system is that there is really no universal standard that assures uniformity. Some makers of filters for non-critical applications, for example, might consider 70% rejection suitable for a nominal filter. Definitions vary from one manufacturer to another, and there is really no way for the end user to verify the claim.

Beta Ratio is less frequently used. It establishes a ratio between the particles that are retained and the particles that pass through the filter. The formula is Particles In divided by Particles Out. Thus, the higher the Beta Ratio rating the better. A beta ratio of 1000 would mean that the filter allows only one particle per 1000 to pass through. A beta ratio of 100 means one particle per 100. The 1000-rated unit, therefore, is 10 times as effective. It should be noted, however, that the beta ratio is no guarantee that the filter will perform as well in areas other than what it was tested for. The filter that works best in one application may not be effective in another.

Types of Sediment Filters

The three broad classes of sediment cartridges are surface filters, depth filters, and adsorptive filters. Depth and surface filters are most common. Which is best depends on what you want the filter to do.

|

|---|

| The micron rating of wound string filters is achieved by varying the winding patterns. Note the differences in the surface of the filters in the picture. Two of the cartridges shown have a stainless steel core which allows them to be used in hot water applications. Most filters of this type have a plastic core. |

Depth Filters require the water being filtered to pass through a thick wall of filter material and treatment takes place throughout the depth of the filter. Some, in fact, have what is called a "graded density" structure, meaning that the filter gets tighter as the water passes through the filter wall. Graded density filters remove particles of a variety of sizes. The outside catches big particles and the inside holds the smaller ones.

Depth filters can be of the wound string type or what is called "melt blown." Wound string is probably the most common. Depth filters are made of a variety of materials, including ceramic, cellulose, polypropylene, acrylic fiber, glass fiber, and polyester.

Ceramic filters are simply extremely tight depth filters made of ceramic. They usually have absolute ratings and are tight enough to filter out microorganisms.

| A manufacturer's depiction of its "graded density" depth filter. Water enters the outside of the filter and flows through the wall toward the inner core. Each layer gets tighter as the water goes in, assuring removal of a wide range of particle sizes. |

Surface Filters are made in a thin sheet so that only the surface traps particles. These are commonly called "pleated filters" because of their accordion-shaped pleated structure. The pleated arrangement gives the filter surprisingly more surface area than depth filters. One of their great advantages is that they are washable and reusable, more so in large than small micron sizes.

To compare: Depth filters have more dirt holding capacity, and they are usually more effective if a variety of particle sizes are being filtered. Pleated surface filters have more surface area and therefore more capacity for filtering particles of a uniform size. It is also easier to manufacture pleated filters to a specific micron size. As stated, they can also be cleaned and reused. Pleated filters can make up for the lack of depth by providing a much larger filter surface area.

|

|---|

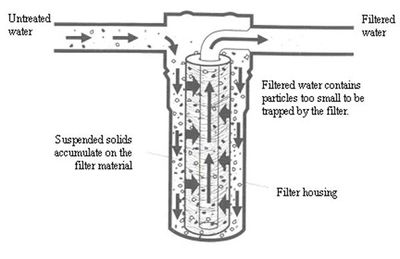

| Virtually all cartridge-style sediment filters follow the "radial flow" pattern seen in the illustration. In a radial flow design, water flows through the wall of the filter into the inner core. This arrangement provides filtering surface that consists of the entire length and circumference of the cartridge. The filter above is a "depth" filter. Pleated filters offer even more filtering surface. |

Adsorptive Filters are becoming more popular. They can be made in either pleated or depth format. Some of these filters are "charged" so that they rely on a process called "electro kinetic adsorption" which enables them to attract and hold negatively charged microorganisms and colloidal matter so small that it easily passes through conventional filters. Adsorptive filters, therefore, can be made in a relatively easy-flowing 2 micron format but they can grab and hold colloidal matter much smaller than 2 microns in size that passes easily through standard filters.

Other Issues

Common questions about sediment filters involve pressure drop, flow rates, differential pressures, and overall filter area. These often have no specific answer and the filter user is left to find what is best for his situation by trial and error.

In general, flow rates for sediment filters are higher than for equally sized carbon or media filters. The tighter the filter, the slower the recommended flow rate is also a generalization you can count on. One manufacturer, for example, gives the following maximum flow rates for its pleated 9.75" X 2.5" filter cartridges:

1 Micron Absolute -- 3 gpm.

2 Micron Nominal -- 4 gpm.

5 Micron Nominal --7 gpm.

20 Micron Nominal -- 8 gpm.

50 Micron Nominal -- 10 gpm.

Carbon block cartridges in the same size are usually rated at a maximum flow rate of 1 gpm, and if serious chemical removal is expected, the flow recommendation would be slower.

Differential pressure measures the difference between the water pressure going into the filter and that coming out. The gap between the two, of course, increases as the filter picks up particulate from the water. A low initial pressure differential means that that filter is offering little resistance to flow. This is a desirable characteristic in most residential filters.

|

|---|

| Sediment Filter In a Clear Housing. The pressure gauges measure the differential pressure to indicate when the cartridge needs replacement. |

The surface area of the filter is an important factor. As stated, pleated filters have much greater surface area than depth filters. Increased area provides more holding capacity and less resistance to flow.

Which Is Best?

For many uses with residential treatment virtually any filter style works well.

For example, a 5-micron wound string sediment is the traditional filter of choice as prefilter for a residential reverse osmosis unit. It serves the purpose--protecting the carbon filter that follows it or the RO membrane from incoming dirt and debris--quite well. However, it can be replaced with virtually any good sediment filter--a melt blown or pleated filter works as well. You could replace it with a 10 micron filter or, if the water is clean, with a 1 micron filter and the RO unit would run fine in most situations.

There are cases, however, where filters aren't interchangeable, and, as indicated, it's sometimes a matter of trial and error discovering what is perfect for the job you have. Often, changing from one style or from one micron rating to another dramatically affects performance. Some customers "swear by" one style or another as the only thing that works well in their application.

|

|---|

| The free-flowing Big Bubba sediment filter offers cartridges in both pleated and depth styles at micron ratings of 1 to 150. The "jumbo" cartridges for the Big Bubba are the largest that we carry. |

Some Flow Rate Figures

Here are suggested maximum flow rates in gpm for the four most common cartridge sizes in Flowmatic (Watts) popular Flow Max series. These are washable and reusable (5 micron and larger) pleated cartridges.

| Micron Rating | 2.5 X 9.75 | 2.5 X 20 | 4.5 X 10 | 4.5 X 20 |

|---|---|---|---|---|

| 1 Absolute | 3 | 6 | 8 | 12 |

| 0.35 Nominal | 4 | 8 | 9 | 13 |

| 1 Nominal | 4 | 8 | 10 | 15 |

| 5 Nominal | 7 | 14 | 15 | 25 |

| 20 Nominal | 8 | 16 | 15 | 25 |

| 50 Nominal | 10 | 20 | 15 | 25 |

Conclusion

Sediment filters are essential tools in water treatment, but choosing one often requires some trial and error. The information presented above can help you make an intelligent choice, but the realities of your specific situation, which almost always involve unknowns like exact particle sizes and flow rate requirements, usually make it necessary to experiment.

The best sediment filter is one that cleans up the water with the least possible restriction in flow and has the longest lifespan.

The Pure Water Occasional is a project of Pure Water Products. Please visit our websites: Main Website; www.purewaterproducts.com This site features our full range of products, plus instructions, technical articles, product manuals, and more. The Occasional's Website: www.purewateroccasional.net. In addition to archiving back issues of the email Occasional, this site houses a sizeable section about water contaminants, a "how things work," series, a new products section, a glossary of water treatment terms, and, "much, much more." Other Pure Water Products Sites: www.purauv.com

|

|---|