How Static Mixers Work

A "static mixer," often called an inline mixer, is a device used frequently in water treatment to create an injection point for chemicals like chlorine and soda ash into a water line. Its purpose is to create turbulence that enhances the rapid mixing of the injected chemical into the water stream. Use of the static mixer can reduce the necessary size of storage tanks following the injection point.

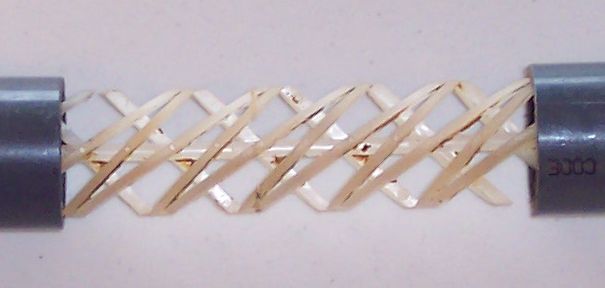

The picture above is a cutaway made to expose the inner workings of the mixer. It's a simple device. The service flow of the water is from left to right in the picture. The chemical is injected through the threaded pipe extension on the left of the mixer body. As water passes through the mixer, it is churned by the metal baffles seen in the picture and the chemical is mixed with the water.

The advantages of using the mixer include reduced residence time requirement and improved performance of the injected chemicals. Disadvantages can be reduced water flow due to restriction and clogging caused by mineral buildup within the device.

Static mixers are also frequently called inline mixers.

|

Inside the Static Mixer |

For more information on feed pump systems and injection devices.