How Whole House Reverse Osmosis Units Work

Large reverse osmosis units work on many of the same principles as small undersink reverse osmosis units, but they have some distinctive features.

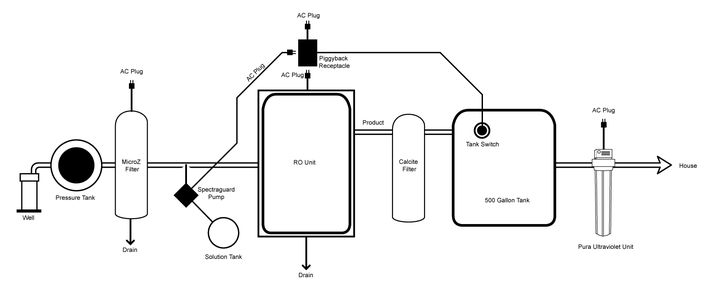

The reverse osmosis unit pictured above is what might be called a "whole house" reverse osmosis unit--one that is suitable in size and performance to supply very high quality water for an entire residence. It could be used for other applications, such as water vending or light commercial situations.

The distinguishing features are the ability to produce a significant amount of water--several hundred gallons per day--and the ability to handle water that is much higher in total dissolved solids (TDS). High operating pressures make that possible.

The picture shows the three distinctive parts of the whole house reverse osmosis unit. On the left is the RO unit itself, which produces the water. In the center is the storage tank. Since reverse osmosis seldom makes water fast enough for the demands of the home, a storage tank is provided so that water will be available upon demand. The storage tank is normally an "atmospheric tank." This means that it is not pressurized, so for water to be delivered to the residence it must go through a pump to repressurize it. Therefore, the final part of the system, on the right in the picture, is the repressurization system. The repressurization system sends the water from the tank under pressure to the point of use.

More Details

1. The RO Unit itself. Water enters the unit at #1, passes through a sediment filter and is picked up by the pump, which sends it under high pressure to the RO membrane--the tall vertical cylinder. Part of the water is forced through the semi-permeably membrane--so tight that it "rejects" almost everything that isn't pure water, including even the mineral content of the water. The greater part of the water, however, leaves the membrane housing as drain water. The drain water washes away the rejected impurities and the product water passes on to the storage tank.

The reject water is called brine and the product water is called permeate.

In most large reverse osmosis units part of the brine is recycled into the inlet stream and sent back for a second pass through the membrane. In multi-membrane units the brine of the first membrane often becomes the feed water of the second membrane, so that the entire brine stream of one membrane is recycled, yielding a "machine efficiency" much higher than the efficiency of a single membrane.

2. The Storage Tank. Filling of the atmospheric storage tank is controlled by a float valve (#6 and #7). When the tank is full of permeate water, a switch turns off the unit and production stops. When water is used from the tank and and the water level falls a few inches below the top of the tank, the float switch starts the unit again and the tank is filled.

3. Repressurization. Water leaves the atmospheric tank at the bottom and is picked up by the repressurization pump. This pump is turned on and off by water pressure. It produces into a smaller tank, this one a pressurized bladder tank. When the bladder tank is full, the pump turns off. When the home demands water, water is delivered from the pressurized tank. When pressure in the small tank goes down to a certain level, the large pump comes on and quickly fills the tank again to full pressure. Some very sophisticated modern pumps can send water directly into the home and do not need the pressure tank.

More about whole house reverse osmosis units

The Watts/Alamo reverse osmosis unit above is identical to the one in the original picture except that a few of the parts are in different places and it has a double RO membrane. Multiple membranes are common in large reverse osmosis units.

Here are some specifics to take note of:

A. The water leaves the pressure pump, upper left on the mounting bracket, and is sent to the lower end of the stainless steel membrane housing on the right. The permeate leaves the membrane housing at the very top and is teed to the the permeate of the second membrane. The brine is routed via the long black tube to the bottom of the second membrane, the one on the left, where it enters as the feed water source. Therefore, the full waste water stream from the membrane at right is fed into the membrane at left to be processed again. Additionally, part of the brine stream from the second membrane can be recycled into the main stream entering the first membrane. The recycling processes allow the entire machine to have a much better permeate-to-brine efficiency than is possible with a single membrane undersink or whole house reverse osmosis unit.

B. The entire operation can be fine-tuned and controlled by the operator. The two glass flow meters, one to the right of each membrane, though somewhat difficult to see in the picture, monitor the outflowing brine and permeate respectively. The operator can see at a glance the gallons-per-minute flow of both the permeate and brine and can, by adjusting the recycling feature and the operating pressure, adjust the unit to achieve optimal performance.

C. Since units of this type often process very challenging water that has high mineral content, most units have an optional flush feature that cleans the membranes at startup and periodically during operation.

Pre-treatment and Post-treatment

Since RO membranes are expensive and sensitive to certain contaminants, they must often be protected with pre-treatment. City water units most often require carbon filtration to remove chlorine or other chemicals. Membranes are destroyed fairly quickly by chlorine. Hardness may also be an issue, and a water softener or hardness sequestering system could be required.

For well water units, pre-treatment is most usually required for iron, manganese, and hardness, which all cause scaling of membranes. Therefore, such devices as water softeners, iron filters, and chemical feeders to inject sequestering chemicals may be required.

As for post-treatment, carbon filtration may be added to remove any chemicals that are not removed by RO membranes or simply for aesthetic improvement. The most common post-treatment, however, is an added calcite filter to increase pH. RO permeate is usually low in pH and a simple calcite filter, which adds calcium carbonate to the water, is often used to bring the pH to neutral.

A typical whole house RO unit is shown below, with pre- and post-treatment.

Here's a good place to go for more information about whole house reverse osmosis units.